PVC Scheinwerfer Reinigen ,Reparieren

Hallo zusammenhab was interessantes gefunden wollte es mit euch teilen

op das stimmt

hat jemand schon mal sowas gemacht

ist aber auf englich

*Disclaimer: Headlight UV protection may be ruined as a result of sanding/wetsanding. Improper use of the materials involved can result in permanent damage to the headlight. Please use caution and attempt this process at your own risk.

*Only use sanding/wetsanding as a last resort if there is no other option for the headlight. Always start out with the least aggressive method which would be polishing by hand or even by maching without wetsanding.

*Best strategy is to get a junk headlight and pratice on that, then duplicate the process on your own headlight. I used my brother Focus lights as practice.

Well, I've got another little write up. I reconditioned my headlight today and thought I'd share the process.

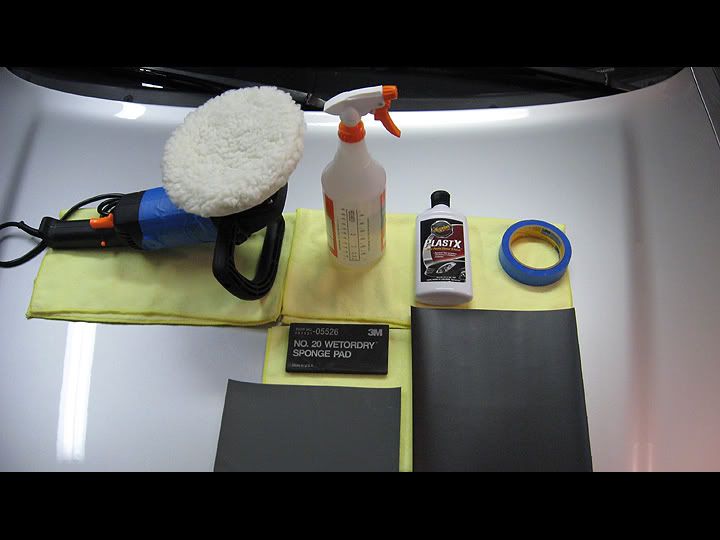

Products used:

3M wet/dry sandpaper,

350 grit(dry)

800 grit

1200 grit

1500 grit

2500 grit

CE Rotary polisher w/wool polishing pad

Plast X

5 gallon bucket

spray bottle with water and 10% detail spray

3M sponge pad

Painters tape

microfiber towels

Process:

Pics of the headlight before I started. Alot of rock chips, scratches, and alittle

oxidation.

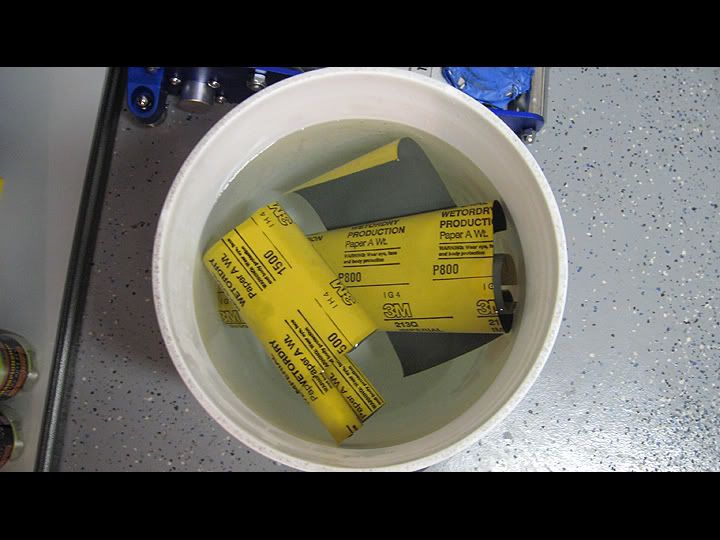

I put sheets of 800, 1200, 1500, and 2500 and let them soak in warm water for thirty

minutes.

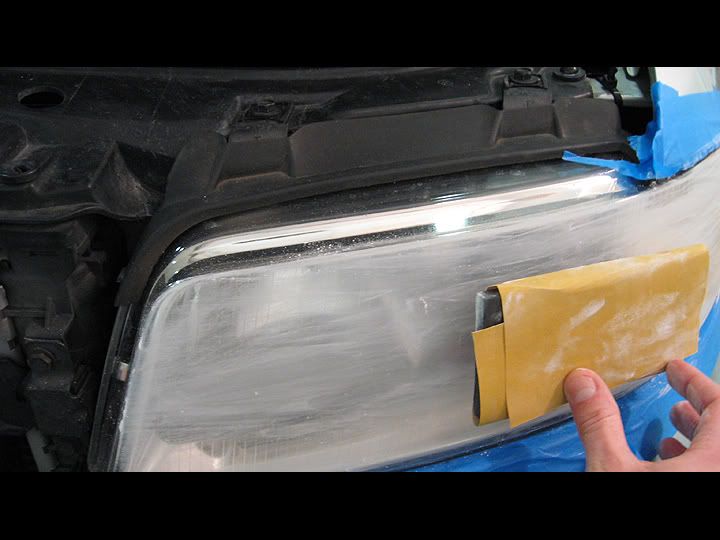

I used painters tape to mask off areas of the fender and bumper that touch the headlight.

Definitely don't want to accidentally sratch the paint.

Then I cleaned the headlight really well and wiped it dry with a microfiber towel.

I wrapped 800 grit(dry) around the sponge pad and started sanding the headlight side to side

in uniform strokes.

800 grit wasn't cutting deep enough to get rid of the rock chips so I stepped up to 350

grit(dry). The 350 worked well and took off a good amount of plastic to expose fresh plastic

below. Saved alot of time, 800 would have taken too long.

Next I used 800 dry, 800 wet, 1200 wet, 1500 wet, and 2500 wet. This is the healight after

the last stage of 2500. All the wetsanding is done and the headlight is dry ready for

polishing.

Now time for polishing with Plast X.

I then setup the rotary with a wool polishing pad and set the speed at 1200 for the first

pass. I started polishing small sections at a time using moderate pressure

Here's a picture just after one pass with the rotary. Already looking great after one pass.

Then I did three more passes with the speed set to 1800

Here the finished headlight pictures. I was extremely happy with how it turned out. Looks

like new.

Danke : Sever

BMW E46

Mitglied: seit 2005

Deutschland

Deutschland

Hallo sever,

schau mal hier auf eBay (klick) - da gibt es sicher etwas passendes zum Thema "PVC Scheinwerfer Reinigen ,Reparieren"!

Gruß

schau mal hier auf eBay (klick) - da gibt es sicher etwas passendes zum Thema "PVC Scheinwerfer Reinigen ,Reparieren"!

Gruß

Ähnliche Beiträge

Die folgenden Beiträge könnten Dich ebenfalls interessieren:

Uha,

ich weiß nicht wo ich hergelesen habe, vieliecht auch sogar in diesem Forum.

Was ich hörte/lies ist, dass die Frontscheinwerfer eine "Härtung" oder Beschichtung haben.

Heißt diese nimmt mann mit dem Schleifen weg. Dann sind zwar kurzfristig alle Kratzer weg, kommen aber deutlich schneller und stärker wieder. Ich glaube nicht, dass die nachträglich aufgebrachte Politur eine solche Beschichtung wiederherstellt. Von daher Vorsicht!

Das Erblinden alter Scheinwerfer kommt nicht wie oft angenommen alleinig durch Steinschläge, sondern durch Alterung des Kunsstoffes.

Cheerio

Bene

ich weiß nicht wo ich hergelesen habe, vieliecht auch sogar in diesem Forum.

Was ich hörte/lies ist, dass die Frontscheinwerfer eine "Härtung" oder Beschichtung haben.

Heißt diese nimmt mann mit dem Schleifen weg. Dann sind zwar kurzfristig alle Kratzer weg, kommen aber deutlich schneller und stärker wieder. Ich glaube nicht, dass die nachträglich aufgebrachte Politur eine solche Beschichtung wiederherstellt. Von daher Vorsicht!

Das Erblinden alter Scheinwerfer kommt nicht wie oft angenommen alleinig durch Steinschläge, sondern durch Alterung des Kunsstoffes.

Cheerio

Bene

Anzeige: